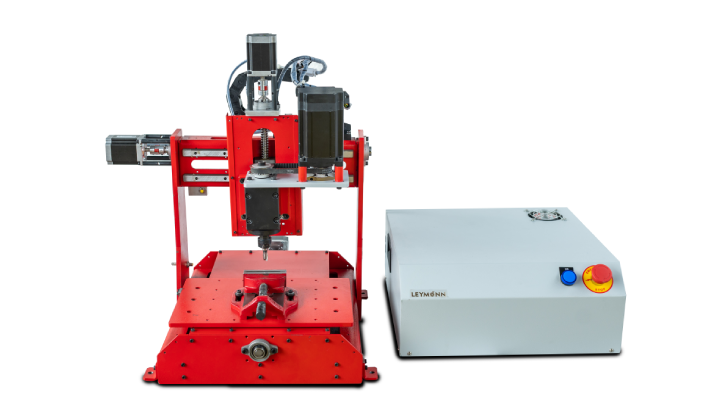

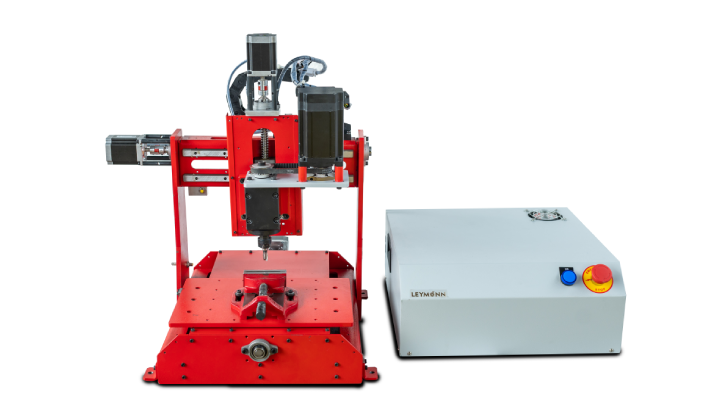

Introducing our 3-axis CNC router machine, a perfect blend of precision and affordability. Equipped with high-precision stepper motors and a powerful spindle, it's ideal for small and large- scale projects, offering a generous X-200mm, Y-240mm, and Z-100mm stroke. What sets us apart is our commitment to quality without breaking the bank. We use top- quality materials and components to ensure durability and exceptional performance Designed for craftsmen and DIY enthusiasts, this machine handles cutting, engraving, and carving on wood, plastic, and metal. User-friendly features like an intuitive control panel and automatic tool changer make operation a breeze. Don't wait; elevate your creativity and craftsmanship with our 3-axis CNC router machine today. Experience unbeatable value and performance with us

Get QuoteKey Features

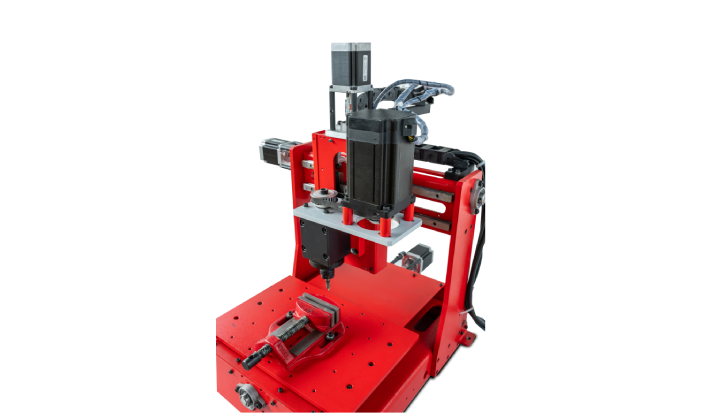

• Multi-Axis Machining: Our 3 Axis CNC Routers enable complex machining operations with

simultaneous control over four axes, expanding creative possibilities and manufacturing

capabilities.

• Precision and Accuracy: Engineered for high-precision cutting, carving, and milling of

materials such as wood, plastics, metals, and composites, ensuring consistent quality in

every project.

• Versatility in Applications: Ideal for industries including aerospace, automotive,

woodworking, and prototyping, these routers excel in producing intricate designs, molds,

and components.

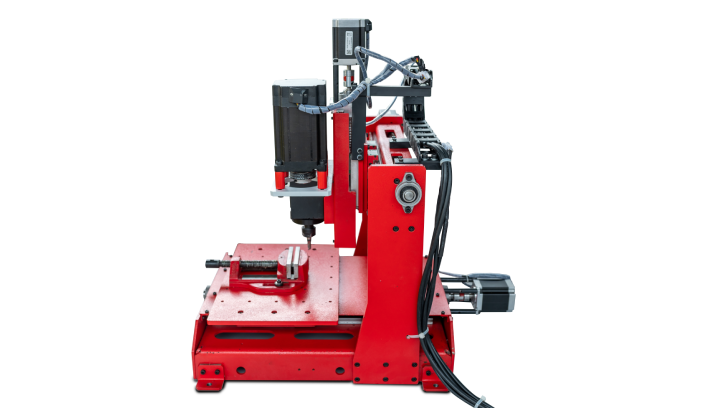

• Efficiency and Speed: Equipped with high-speed spindles and advanced motion control

systems, our machines optimize production efficiency without compromising on quality.

Features

3 Axis CNC Router

Perfect for Metal And Wood

Machine Specification

| X Axis Traverse | 200 mm |

| Y Axis Traverse | 240 |

| Z Axis Traverse | 100 mm |

| Spindle | BLDC Motor |

| Spinde Speed | 100-3000RPM Infinitely variable |

| Spinde Chuck Collet | ER 16 Collet Holder |

| Working Area | 228×340 mm |

| Controller | PC based Controllers / Rich Auto / MeteorCNC |

| Distance Between Centers | 200 mm |

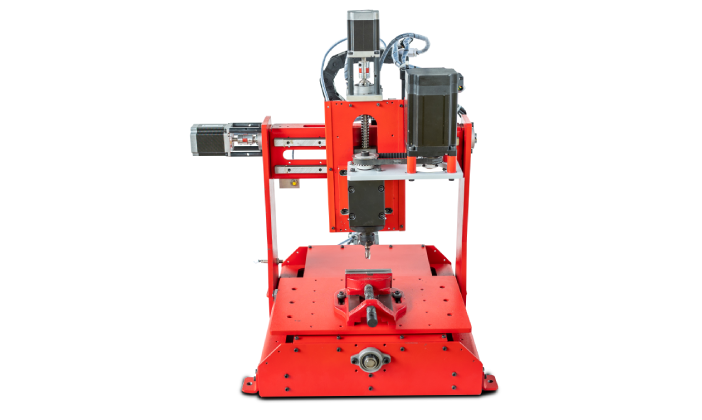

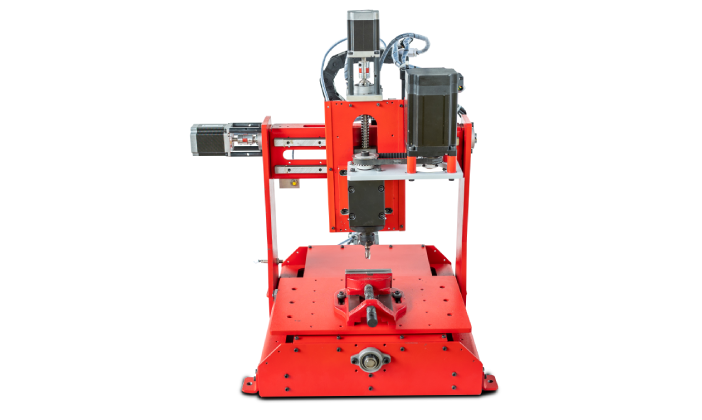

• Built with a sturdy, stable structure suitable for woodworking and metal production applications.

• Ensures precision and durability in every cut and production process.

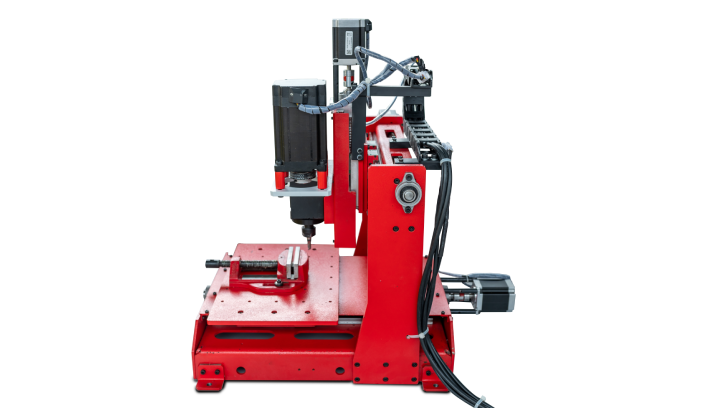

• Woodworking: Ideal for crafting intricate designs and precise cuts in wooden panels, furniture components, and artistic woodwork.

• Metal Production: Capable of machining metal parts with accuracy and efficiency, supporting industries such as automotive, aerospace, and general manufacturing.

• Advertising and Signage: Creates customized signage, 3D letters, and decorative elements with fine detail and accuracy, meeting the demands of the advertising industry.

• Prototyping: Facilitates rapid prototyping of new products and designs, enabling iterative development and testing across various materials.

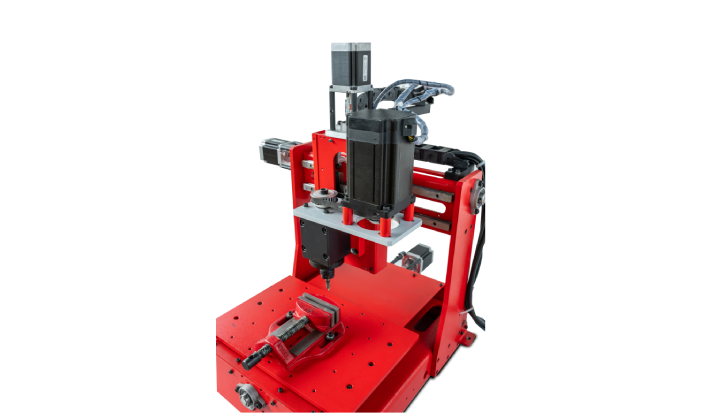

• High Precision: Offers high-level accuracy and repeatability, crucial for detailed and complex designs in both wood and metal.

• Versatility: Handles a wide range of materials including wood, metals, plastics, and composites.

• Efficiency: Optimizes production processes, reducing lead times and costs associated with manufacturing across different materials.

• Customization: Accommodates custom projects easily, meeting unique design requirements in diverse industries.

• Incorporates advanced technology to enhance operational efficiency and quality in both wood and metal machining.

• Constantly updated with the latest innovations to maintain competitiveness and meet evolving industry standards.

• Enhances productivity and output quality, ensuring customer satisfaction and loyalty in both woodworking and metalworking applications.

• Supports businesses in meeting deadlines and scaling production capabilities effectively.

• Provides a reliable and durable solution for long-term operational needs across various materials.

• Illustrates specific applications within each industry segment, showcasing real-world examples of the machine's capabilities in woodworking and metal production.

• Highlights success stories and case studies demonstrating the machine's impact on improving production processes and product quality in diverse manufacturing environments.